CNC (Computer Numerical Control) milling is a cornerstone technology in modern manufacturing, enabling the precise and efficient shaping of metal and other materials. At its core, CNC milling revolves around removing material from a workpiece to achieve a desired design, driven by computer-controlled, automated machinery. This process is critical for industries requiring high precision and repeatable results, such as aerospace, automotive, and electronics.

The CNC Milling Process

The journey from a raw material to a precision component involves several meticulously executed steps in CNC milling:

- Design and CAD Modeling: The process begins with detailed CAD (Computer-Aided Design) modeling, where engineers create accurate 3D models of the intended products. These models are crucial for visualizing the final product and making necessary adjustments before the manufacturing phase.

- CAM Programming: Following the design phase, CAM (Computer-Aided Manufacturing) programming is crucial. This stage converts the CAD models into G-code, which the CNC machines can interpret. CAM software optimizes the tool paths to maximize efficiency and minimize material waste.

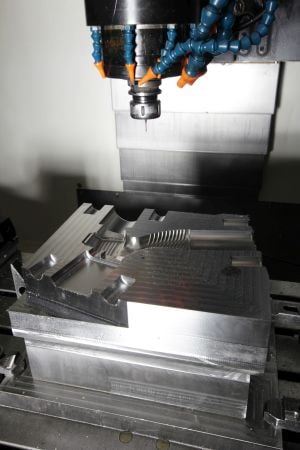

- Machine Setup: Preparing a CNC milling machine for production involves loading the appropriate tools and securing the raw material in place. Precision calibration of the machines ensures that they align perfectly with the project specifications.

- Milling Process: In the milling stage, cutting tools systematically remove material from the workpiece according to the CAM program. This phase can incorporate various operations such as drilling, boring, and cutting with precision. The automation of CNC milling allows operations to continue around the clock with minimal human oversight.

- Quality Control and Finishing: Each milled part undergoes strict quality control to ensure it adheres to the required specifications. Necessary finishing touches like sanding, polishing, or anodizing are applied to achieve the desired surface quality and functionality.

- Final Inspection and Delivery: The last step is a comprehensive inspection to verify that each component is flawless and meets quality standards. Once confirmed, the parts are securely packaged and readied for shipment.

This streamlined and precise process is reflective of the advanced capabilities found in modern CNC milling operations, ensuring that each component is crafted to meet high standards of quality and performance.

Parts Manufactured Using 3-Axis and 4-Axis CNC Milling

At ICON.Engineering, besides 5-axis machining, we also specialize in 3-axis and 4-axis CNC milling, which allows us to efficiently produce a broad range of components with varying complexities. These milling processes are essential for parts that require high levels of precision and excellent surface finishes. Here’s an overview of the components we fabricate using 3-axis and 4-axis CNC milling technologies:

Industrial Machinery Components:

- Base plates and fixtures that provide structural support and stability.

- Gear blanks before the gear teeth are cut, requiring precise dimensions for further processing.

- Custom jigs and fixtures designed to hold parts in the exact position during the manufacturing process.

Automotive Parts:

- Engine blocks that form the powerhouse of the vehicle.

- Transmission cases which house the gears, shafts, and bearings of automotive transmissions.

- Complex brackets that support various mechanical and electrical components within the vehicle.

Consumer Electronics:

- Enclosures for electronic devices that require precise dimensions for assembly.

- Heat sinks designed to dissipate heat efficiently from electronic components.

- Structural frames that provide rigidity and durability to the devices.

Aerospace Parts:

- Structural panels used in the fuselage and wings of aircraft.

- Bracketry for mounting engines and other critical systems.

- Satellite components that require ultra-precise machining for proper fit and function in space applications.

Medical Industry:

- Bone plates and other orthopedic implants that assist in the healing process.

- Surgical instruments designed for specific medical procedures.

- Custom casings for high-tech medical equipment.

Types of CNC Milling Machines

CNC milling machines vary significantly in design and capability, each tailored to meet specific industrial needs. Understanding the different types of milling machines helps in appreciating their roles in manufacturing complex components:

- Vertical Milling Machines: These machines feature a vertically oriented spindle that approaches the workpiece from above. Vertical mills are highly versatile and ideal for jobs that require a mixture of drilling and milling. They are commonly used for the precision milling of slots, grooves, and other features on a workpiece.

- Horizontal Milling Machines: In contrast to vertical machines, horizontal milling machines have a spindle oriented horizontally. This design allows for the mounting of multiple cutting heads, making them suitable for removing material over large surface areas quickly. They are particularly effective for projects involving heavy materials or rapid material removal.

- Turret Mills: Turret mills, a type of vertical mill, offer versatility and flexibility in machining. They feature a stationary spindle and a table that moves both perpendicular and parallel to the spindle axis to cut the material. This machine is excellent for more precise milling tasks such as creating complex shapes and angles.

- Bed Mills: Bed mills also fall under the vertical mill category but differ as the table moves only perpendicular to the spindle’s axis, while the spindle itself moves parallel. This design provides more rigidity and is thus better suited for heavier milling loads.

- CNC Router: Although not traditionally categorized under milling machines, CNC routers are similar in concept and operate with greater speed and less torque than typical milling machines. They are perfect for softer materials like wood, plastics, and foam.Each type of CNC milling machine brings its own set of capabilities and is chosen based on the specific requirements of the project, including the material’s hardness, the complexity of the design, and the required precision. The selection of the right machine is critical to achieving the best results, ensuring efficiency, and minimizing waste.

CNC Milling Operations

CNC milling machines are highly versatile, capable of performing a variety of operations that allow for the creation of complex geometries and intricate details. Here’s a look at some of the most common operations:

- Drilling: Drilling is a fundamental operation where a rotating cutting tool is used to create round holes in the material. It’s a straightforward process but requires precision to ensure the holes are correctly sized and properly positioned.

- Boring: Boring is used to enlarge holes or bring them to precise dimensions. This operation is particularly important when a high degree of accuracy and finish is required within the hole’s interior surfaces.

- Thread Milling: Thread milling is used to create threads in the interior of a hole, allowing for the insertion of bolts or other threaded components. This operation provides greater accuracy than traditional tapping, especially in hard materials.

- Slot Milling: Slot milling involves the cutting of grooves into the surface of the material. This can be particularly challenging as it requires precise control over the depth and width of the slot.

- Face Milling: Face milling is used to create a flat surface or to face off material from the surface to achieve a high level of surface finish. The milling cutter is typically large in diameter and makes broad, shallow cuts.

- Profile Milling: This operation involves shaping the exterior of a workpiece. Profile milling is used to cut complex contours and reduce the workpiece to the desired form. It can involve both vertical and horizontal milling machines.

These operations highlight the flexibility of CNC milling, enabling the production of parts with a variety of features and specifications. The choice of operation depends on the part design, material properties, and the required precision, all of which are expertly managed to ensure optimal results.

Materials and Products

CNC milling is a versatile manufacturing process capable of handling a wide array of materials, each offering distinct benefits and suited for specific applications:

Metals:

- Aluminum: Lightweight yet strong, aluminum is one of the most commonly milled metals due to its ease of machining and good corrosion resistance. It is ideal for aerospace, automotive, and consumer electronics applications.

- Stainless Steel: Known for its strength and corrosion resistance, stainless steel is frequently used in medical devices and food processing equipment.

- Brass: Brass is often chosen for its machinability and aesthetic appeal, making it popular for decorative items, as well as fittings and components that require low friction.

Plastics:

- Acrylic: Used for its clarity and resistance to breakage, acrylic is often milled for use in optical applications and consumer products.

- Nylon: Known for its strength, wear resistance, and insulation properties, nylon is commonly used in automotive components and mechanical parts.

Composites:

- Carbon Fiber Reinforced Polymer (CFRP): CFRP is known for its strength-to-weight ratio and is commonly used in the aerospace and automotive industries for high-performance parts.

The choice of material not only affects the milling process but also influences the type of product that can be manufactured:

- Aerospace Components: High-strength metals and composites are used to produce lightweight, durable components.

- Medical Implants and Tools: Stainless steel and titanium, known for their biocompatibility, are preferred.

- Electronic Housings and Insulators: Plastics like acrylic and nylon are chosen for their insulating properties and ease of machining.

The ability to work with such a diverse range of materials underscores the flexibility of CNC milling, making it indispensable in the production of complex and precision parts for a wide range of industries. Each material brings its own set of challenges and benefits, which ICON.Engineering navigates with expertise to deliver products that meet high-quality standards.

Advantages of CNC Milling

CNC milling offers several significant advantages that make it a preferred method for manufacturing complex parts across various industries:

- Precision and Accuracy: CNC milling machines operate with high precision, capable of achieving tolerances within thousandths of an inch. This level of accuracy is essential for industries like aerospace and medical devices, where even minor deviations can have significant consequences.

- Consistency and Repeatability: The automated nature of CNC milling ensures that each part is produced with the same specifications and dimensions, crucial for large production runs where consistency is key.

- Complex Geometries and Customization: With advanced CAD and CAM technologies, CNC milling can produce parts with complex shapes and intricate details that would be difficult, if not impossible, to replicate manually. This capability allows for high levels of customization in product design.

- Efficiency and Speed: CNC milling significantly reduces production time compared to manual processes. The ability to operate continuously and perform multiple operations without human intervention speeds up the manufacturing cycle, leading to faster turnaround times.

- Material Versatility: As discussed, CNC milling can handle a variety of materials, from metals to plastics and composites, making it a versatile option for different industrial applications.

- Cost-Effectiveness: Although the initial setup cost for CNC milling machinery can be high, the long-term savings are substantial due to the reduced labor costs, decreased waste, and minimized errors. This makes CNC milling a cost-effective solution for both short and long production runs.

The advantages of CNC milling reflect the commitment to quality and efficiency in modern manufacturing. By leveraging these benefits, industries can produce high-quality, precise, and durable parts that meet the stringent demands of today’s markets.